Q-LON vs. EPDM

Made with a unique combination of materials and with technical performance unmatched by any other material used in seals, Schlegel Q-LON offers the highest standard of sealing function –even under extreme conditions.

Independent Testing

Q-LON has been extensively tested by independently certified test

facilities that clearly demonstrate its superior performance over other

commonly used seal materials, like EPDM.

As shown in the below comparative testing, Q-LON seals retain their properties and

performance significantly better over time when, after 10,000 cycles of opening

and closing, EPDM seals lose their ability to meet the normal operational

requirements. Areas affected include weathering performance, thermal

insulation, sound attenuation and air tightness. under extreme conditions.

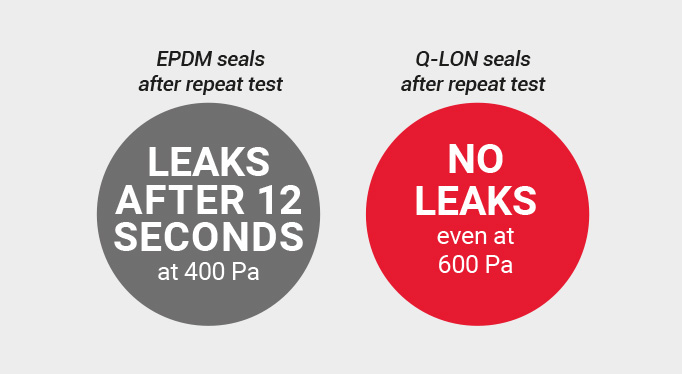

Each seal was tested for air permeability and water tightness in two steps.

- Initial test: EPDM and Q-LON seals were tested on identical brand new windows.

- Repeat test: the windows underwent 10,000 full operation cycles, equivalent to a 15-years life cycle, and they were then tested again under the same conditions as the initial test.

The repeat test gives a measure of the seal’s ability to perform after intense usage.

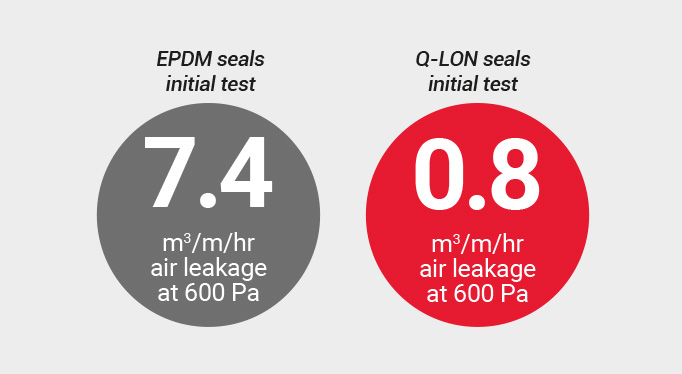

Air Permeability test*

Q-LON performed significantly better for air permeability during the initial test, but it also continued to provide an effective seal, even after 10,000 full operations of the window. After the repeat test, the performance variance was just 2.33%. EPDM seals provided significantly less effective proofing against draughts during the initial test, and they also experienced a drastic drop-off after 10,000 operations: they were 28% less effective after the repeat test.

Water tightness test*

EPDM performed well initially, but its effectiveness was degraded significantly following the cycle test, indicating that water tightness will decrease with time. Q-LON was proven to provide the same level of performance throughout a the service life of a window, thus it is suitable for windows requiring exceptionally high weather resistance.

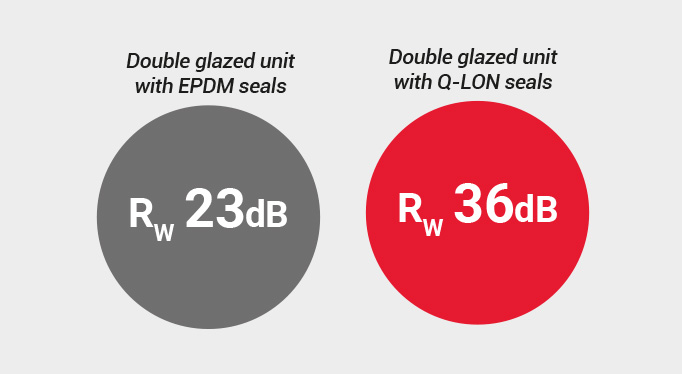

Acoustic insulation test**

The Weighted Sound Reduction Index (Rw) rates the effectiveness of a soundproofing material. Increasing the Rw by one equates to 1dB in noise reduction. Q-LON equipped windows proved able to reduce outside noise by 13 decibels when compared to EPDM seals mounted on the same window.

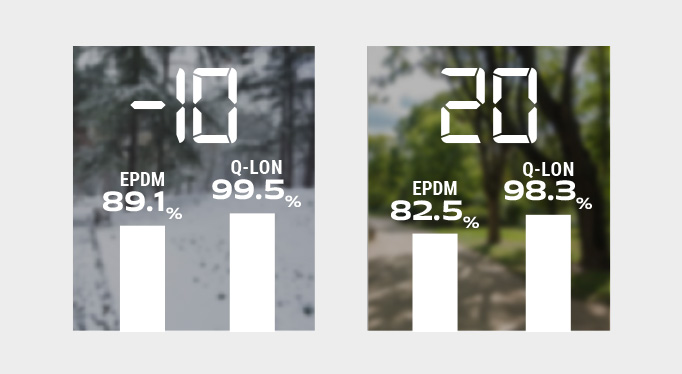

Compression recovery test

This is a measure of the ability of a seal to recover its original dimensions following a period of compression under extreme temperature conditions. In this test, seals were compressed to 50% for seven days and then given 24 hours to recover. The numbers expressed above are the percentages by which the seals had reverted to their original dimensions after the 24-hour period elapsed. Q-LON recovers over 10% more when compared to EPDM seals, even at frigidly cold temperatures, thus continuing to perform effectively over an extended lifetime.

* Initial and repeat test in accordance with BS 6375-1 under UKAS accredited conditions. 10,000 full cycles of operation before the repeat test in accordance with BS 6375-2

** Test conducted in accordance with BS EN ISO 10140-2, under UKAS accredited conditions.

Download Q-LON vs. EPDM brochure